Detector Design at Brown

Our students have the unique opportunity for hands-on detector design for the Large Hadron Collider (LHC) at CERN with Professor Ulrich Heintz's group. Students work at Brown and at CERN toward the goal of replacing the LHC's tracker.

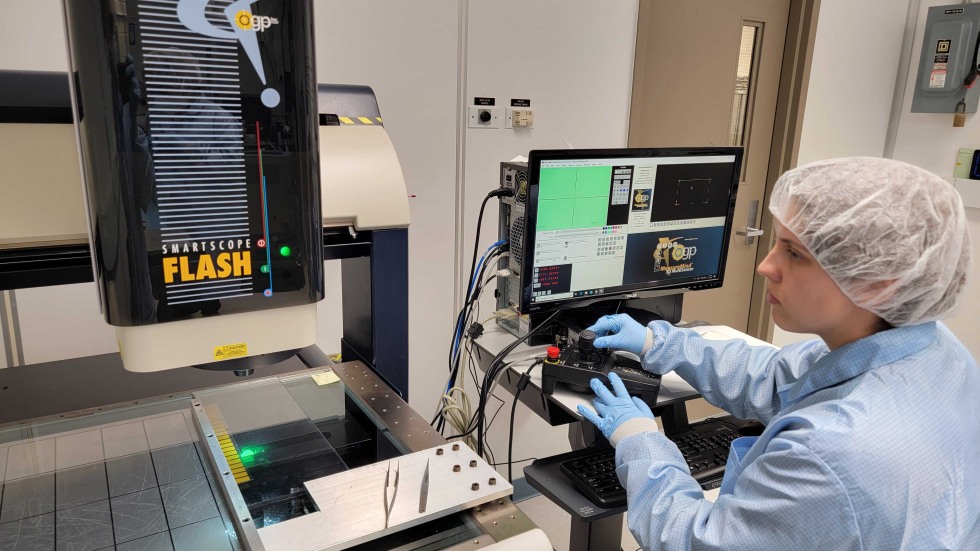

Prof. Heintz's advisee, Ph.D. student Samantha Sunnarborg, works on the LHC tracker in the clean room. Upon completion of the tracker, Prof. Heintz says that "the students can participate in setting up the detector at CERN and making sure all the components work," a uniquely Brown physics experience! Photo: Ulrich Heintz

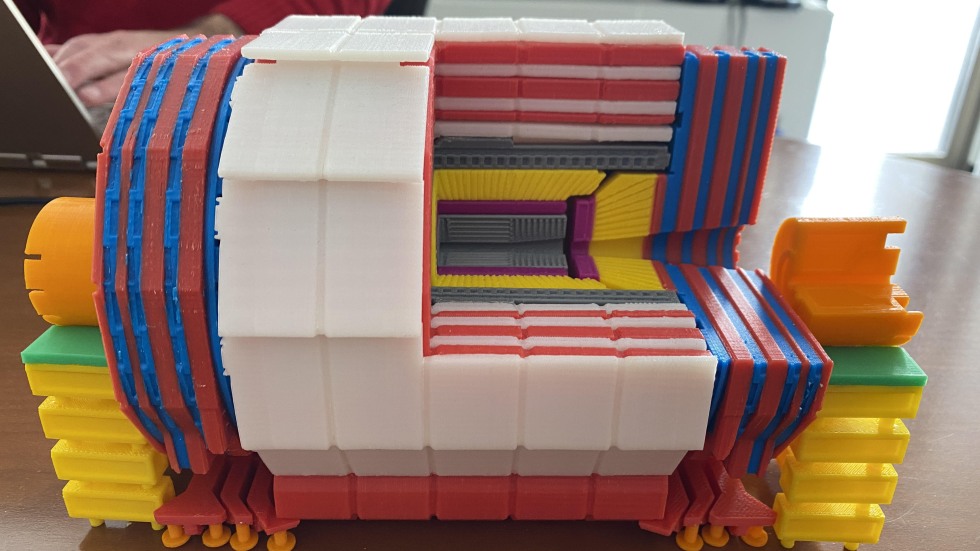

Prof. Ulrich Heintz's 3D printout of a detector. The gray component, the tracker, is the piece that Prof. Heintz and his students are building for the Large Hadron Collider at CERN. Photo: Valerie DeLaCámara/Brown University

Professor Ulrich Heintz and his research group are designing and building a critical replacement component for the Large Hadron Collider at the European particle physics lab (CERN), and Brown students have a front-row seat in this fascinating project. In the United States, there are exactly two places where this work is happening: Fermi National Lab and right here at Brown. Brown students have the unique opportunity to contribute to the process, both in Heintz's lab and at CERN.

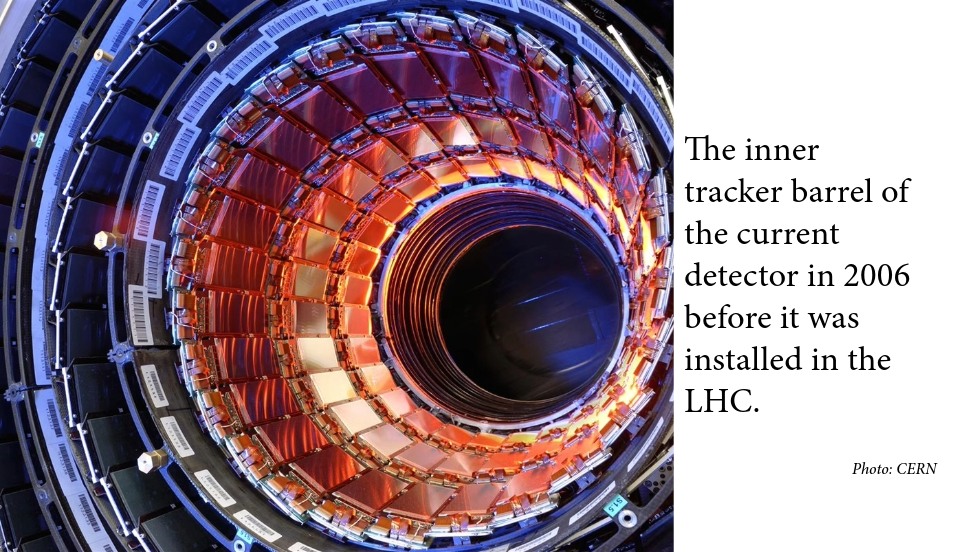

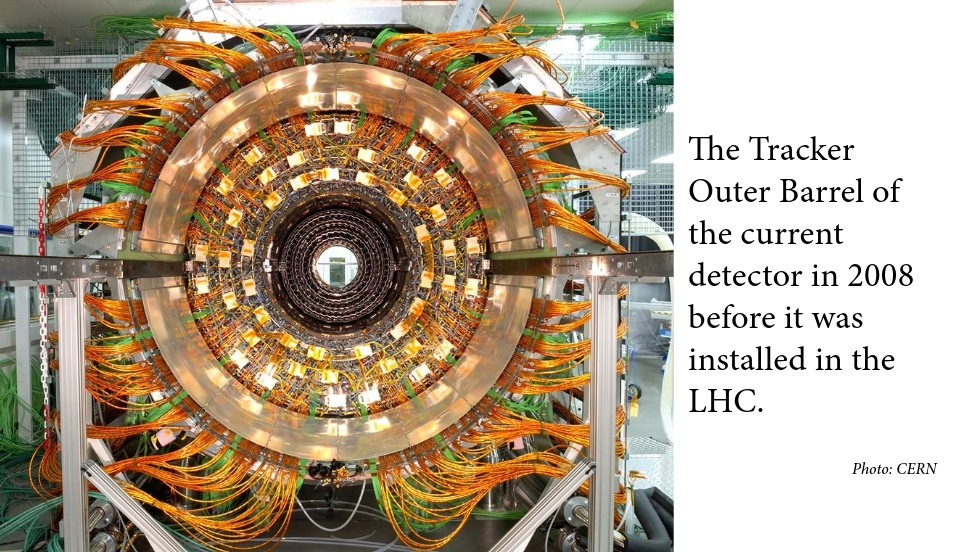

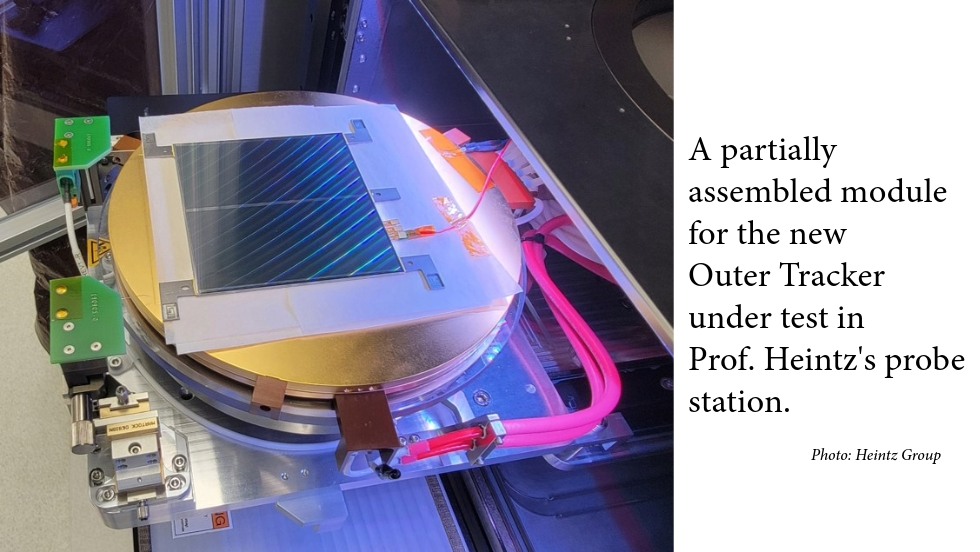

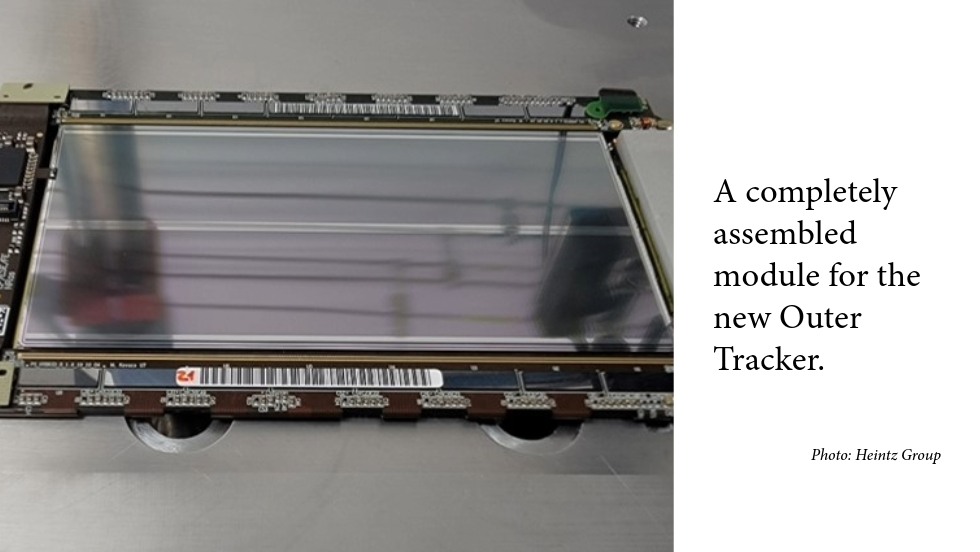

Heintz elaborates: “We’re building part of a particle detector for the high-luminosity program of the Large Hadron Collider. More specifically, we build modules for the tracking detector of the Compact Muon Solenoid (CMS) experiment by precisely assembling silicon sensors and readout electronics here at Brown. These modules will then be transported to Europe, to be integrated into larger sections. Eventually, these are assembled at CERN to make up the tracker for the CMS experiment.”

The work at Brown began over ten years ago with extensive research and development. It is hard to believe, Heintz says, that they are now finally going into production with the assembly of the modules. He says that at every stage, there have been opportunities for students to participate in the development of what sensors to use, how to measure certain properties of the sensors, and how to assemble the components. Students are trained to work with great precision, Heintz emphasizes. “The sensors are very delicate, and they have to be very precisely aligned during assembly because we want to have position resolutions of tens of micrometers.”

Students played a big role in testing the silicon sensors. Heintz says, “We teach them how to measure the properties of the silicon sensors, determine whether they satisfy our specifications, and whether they can go into the detector. We study how these properties evolve once they are exposed to continuous radiation in the detector over a period of ten years in the LHC. We conduct modeling and perform experiments in which we irradiate samples, exposing them to neutrons, for example, at a nearby research reactor." Students can then measure how the properties of the detector change. “The more proficient students become, the more opportunities they have to become involved with more complicated projects.”

The modules are technically complex because they are manufactured at room temperature, around 20 to 25°C, but they will be operated at about -30°C. This is a temperature difference of 50°C.” When the module cools down, the different elements in the module contract. If they contract at different rates, then the whole thing may crack or deform, Heintz says. The materials must be chosen so that their thermal expansion coefficients are well-matched, and the parts must be assembled carefully so that all glue joints are strong. Further explaining the process, Heintz continues, “The modules contain thousands of delicate wire connections between the sensor and the read-out electronics. Nevertheless, they must be designed to be mechanically robust. Once the modules are installed in the detector, they must function reliably for at least 10 years, as we won't be able to access them afterward.

When students participate in the construction, they learn how such a detector works and how it is built. We aim to educate students in all aspects of detector design, as they will build the next generation of experiments. It's a rather unique opportunity, because the timescale over which these experiments are built is quite long.” Heintz emphasizes that the opportunity does not exist at every institution, and certainly not in the United States, noting that Brown students are fortunate to participate in this work and gain valuable technical skills they cannot get elsewhere.

The Department of Energy funds the group to support students if they participate in the program here. In exchange, they will learn how particle detectors work, how to design and build them, and how to operate them. Heintz says that there are jobs within the project for students at all levels. Graduate students can see how the detector is made while analyzing data from the current detector. Ultimately, he says, understanding what's involved in making the detector components and how they work, will help the students understand their analysis work better.

The CMS experiment, with which Heintz’s group is working, began this effort almost 20 years ago, and it is still about five years away from final installation at CERN. Most students who work on the project ultimately may not be involved at the project's conclusion.

For the next two years at least, Heintz says the focus will be here at Brown. Then the work will move to CERN. He says, “Right now, we have students go to CERN and work on operating the current detector. There's a whole range of things that the students can learn about a detector. They work with our group at CERN on the current detector and understand how that works. They also work with us here at Brown and see how you actually build a detector and put it together.” In reflection, Heintz says. “There is no limit to what they can learn.”